In todays competitive and detail-oriented market, packaging and protective storage are no longer just functional necessities—they are strategic tools that reflect brand identity, product value, and operational efficiency. The aluminum case has become a leading choice for secure storage and transport across industries due to its durability, lightweight structure, and modern appearance. More importantly, advances in aluminum case customization now allow businesses to create tailored solutions that align precisely with their technical, visual, and branding needs.

This guide explores the full range of custom aluminum case solutions, breaking down the key structural, material, and aesthetic options available.

A standard aluminum case may serve basic purposes, but a custom aluminum case offers far greater value. Customization allows the case to be designed around the specific product it carries—offering better protection, improved organization, enhanced appearance, and more efficient use of space.

Aluminum case customization also plays a critical role in brand positioning. When a case carries the right colors, logo, surface materials, and interior configurations, it becomes an extension of the product brand itself. This is especially important for professional applications such as tools, cosmetics, electronics, instruments, and specialized equipment.

The aluminum frame is the foundation of any aluminum case. Different structural shapes provide different levels of support, durability, and style. Common frame options include:

L Shape – Lightweight and simple, ideal for compact and portable aluminum case designs

R Shape – Rounded edges provide a smoother look and enhanced strength

K Shape – Thicker and more reinforced, suitable for heavy-duty use

Combined Shape – A customized blend of profiles for specialized structural requirements

Choosing the right frame is essential for ensuring that a custom aluminum case performs well under its expected conditions.

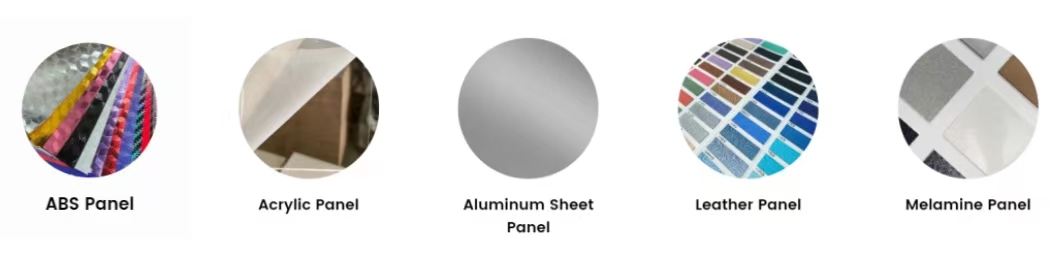

Panel material plays a crucial role in both function and appearance. Through aluminum case customization, multiple panel options can be selected based on protection needs, aesthetic preferences, and budget.

ABS Panel – Lightweight, impact-resistant, and cost-effective

Acrylic Panel – Glossy, modern, and sleek

Aluminum Sheet Panel – Maximum strength and durability

Leather Panel – Premium and elegant appearance

Melamine Panel – A balanced choice between strength and affordability

Each material can transform the look and feel of an aluminum case, allowing it to fit different product categories and target markets.

Color customization is a key part of modern custom aluminum case solutions. Whether the goal is to match a brand’s color palette, create a bold visual impact, or maintain a clean and professional aesthetic, aluminum cases support full color customization.

By providing a simple color reference, businesses can achieve fast, accurate, and consistent color matching. This capability allows brands to maintain uniformity across product lines, marketing materials, and packaging.

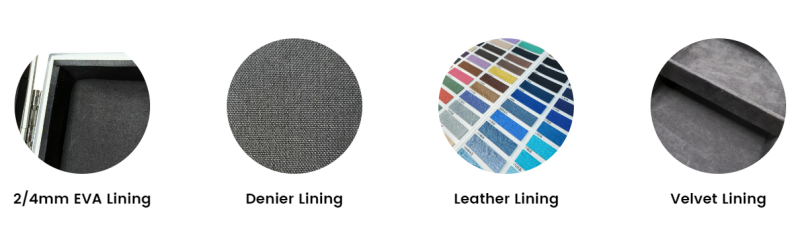

The interior of an aluminum case is just as important as the exterior. The right internal structure increases protection and enhances the user experience. Several lining materials are available:

2/4mm EVA Lining – Shock-absorbing and lightweight

Denier Lining – Durable and practical

Leather Lining – Sophisticated and luxurious

Velvet Lining – Soft, elegant, and protective

These lining options can be combined with partitions or layers to create a highly organized, professional interior layout.

Foam padding is one of the most essential components of a custom aluminum case. It protects contents from vibration, impact, and movement during transportation or storage. Available foam types include:

EVA Foam – Strong, resilient, and long-lasting

Flat Foam – Simple base protection

Model Foam – Custom-shaped for specific products

Pearl Foam – Lightweight and flexible

Pick and Pluck Foam – Easy to modify for different item layouts

Wave Foam – Ideal for lid cushioning and top-layer protection

Foam inserts can be precisely designed and cut to match the exact shape and size of the enclosed items, making aluminum case customization highly efficient and product-specific.

A professionally-branded aluminum case strengthens brand identity and creates a premium impression. Multiple logo application techniques are supported:

Debossed Logo – Subtle, engraved branding for a classy finish

Laser Logo – Precise, modern, and permanent

Screen Printing on Case Panel – Bold and colorful presentation

Screen Printing on Aluminum Sheet – High-contrast, industrial look

These branding options elevate a basic aluminum case into a marketing and presentation asset.

One of the biggest advantages of custom aluminum case solutions is flexibility. Whether the requirement is for a compact case or a large, multi-layered storage system, customization allows for adjustments in:

Size and dimensions

Internal layout

Hardware components (handles, locks, hinges, corner protectors)

Surface textures

Application-specific features

This ensures each aluminum case is not just a container, but an optimized tool that supports efficiency, safety, and professional presentation.

At Foshan Nanhai Lucky Case, we specialize in full aluminum case customization from concept to production. We support every option described above, including frame structures, panel materials, personalized colors, interior linings, custom-cut foam, and advanced logo applications. Other requests are always welcome, and we provide free design services to bring custom aluminum case ideas to life.

Our focus is to deliver reliable, high-quality custom aluminum case solutions that match exact functional and branding requirements. With professional expertise and flexible production capabilities, we ensure every aluminum case we produce is tailored to meet precise needs with accuracy and efficiency.